In the rapidly evolving field of robotics, 3D vision systems for robots are transforming how machines perceive and interact with their environment. Unlike traditional 2D cameras, these systems provide robots with spatial awareness, enabling them to perform complex tasks with increased accuracy and efficiency.

This article explores the fundamentals of 3D vision technology for robots, its applications across industries, the various types of systems available, and the key benefits they offer. Whether you’re a robotics engineer, automation specialist, or tech enthusiast, understanding 3D Vision Systems for Robots is essential for appreciating the next wave of robotic innovation.

What Are 3D Vision Systems for Robots?

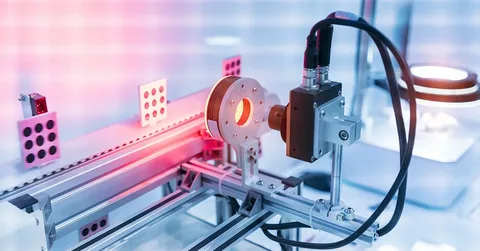

At its core, a 3D vision system for robots is a technology setup that equips robots with the ability to “see” and interpret three-dimensional space. These systems combine hardware such as cameras, sensors, and projectors with sophisticated software algorithms to capture and process depth information from the robot’s surroundings.

Unlike flat 2D images, 3D vision delivers rich spatial data, including distance, shape, volume, and position of objects relative to the robot. This enhanced perception allows robots to navigate environments, identify objects, and manipulate items with unprecedented precision.

Components of 3D Vision Systems for Robots

- 3D Cameras/Sensors: Devices such as stereo cameras, time-of-flight (ToF) sensors, and structured light projectors capture depth data.

- Processing Unit: Dedicated processors or AI chips analyze the raw data, creating a 3D map or model.

- Software Algorithms: Computer vision and machine learning software interpret the data for object recognition, navigation, and decision-making.

Why Are 3D Vision Systems Critical for Robots?

Traditional robots rely heavily on pre-programmed movements and 2D visual data, limiting their adaptability. 3D vision systems for robots bring several critical improvements:

- Enhanced Spatial Awareness: Robots can accurately judge distances and avoid obstacles.

- Improved Object Recognition: 3D data helps differentiate between objects with similar color or texture.

- Greater Flexibility: Robots can handle irregularly shaped items and work in dynamic environments.

- Safer Human-Robot Interaction: Depth perception allows robots to detect human presence and adjust their movements to prevent accidents.

Types of 3D Vision Systems for Robots

Several technologies power 3D vision, each suited for different applications and environments.

1. Stereo Vision Systems

Stereo vision mimics human binocular vision by using two cameras spaced apart. By comparing the images from each camera, the system calculates depth through triangulation. Stereo vision is cost-effective and suitable for outdoor and industrial environments but can struggle in low-light or textureless scenes.

2. Time-of-Flight (ToF) Cameras

ToF cameras emit infrared light pulses and measure the time it takes for light to reflect back from objects. This time measurement translates into precise distance data. ToF sensors are compact, provide real-time depth information, and excel in both indoor and outdoor applications.

3. Structured Light Systems

These systems project a known light pattern (e.g., grid or stripes) onto objects and capture the deformation of this pattern to determine depth. Structured light offers high accuracy and resolution but can be sensitive to ambient light interference.

4. Laser Scanners and LIDAR

Laser-based 3D vision systems scan environments using laser beams to create detailed point clouds. LIDAR is widely used in autonomous vehicles and robotics for mapping large spaces with great precision.

Applications of 3D Vision Systems in Robotics

The versatility of 3D vision systems for robots allows them to enhance performance in many industries:

Manufacturing and Assembly

3D vision enables robots to identify parts, measure dimensions, and perform precise assembly even with variable shapes and sizes. It significantly reduces error rates and increases production speed.

Warehousing and Logistics

Robots equipped with 3D vision can pick, sort, and stack irregular items efficiently. They navigate cluttered warehouse spaces, avoid collisions, and optimize routing, improving fulfillment speed and safety.

Healthcare and Surgery

Surgical robots use 3D vision to map human anatomy, guide instruments, and assist surgeons with minimally invasive procedures, enhancing accuracy and patient outcomes.

Agriculture

In farming, 3D vision helps robots identify ripe fruit, measure crop health, and navigate uneven terrain for tasks such as harvesting and spraying.

Autonomous Vehicles and Drones

Vehicles and drones rely on 3D vision to detect obstacles, map environments, and make real-time navigation decisions to ensure safe travel.

Advantages of Using 3D Vision Systems for Robots

Incorporating 3D vision into robotic systems delivers several powerful benefits:

- Precision and Accuracy: Depth perception allows for millimeter-level precision in manipulation tasks.

- Adaptability: Robots can adjust to changing environments and unknown objects without manual reprogramming.

- Increased Efficiency: Automation processes become faster and less error-prone.

- Cost Savings: Reduced waste, improved quality, and lower labor costs contribute to ROI.

- Improved Safety: Robots can better avoid humans and hazardous objects, making collaborative robotics safer.

Challenges and Considerations When Implementing 3D Vision Systems

While promising, integrating 3D vision systems is not without challenges:

- High Initial Costs: Advanced sensors and processing units can be expensive.

- Complex Calibration: Accurate depth measurements require precise calibration.

- Data Processing Demands: 3D vision generates large amounts of data, necessitating powerful computing resources.

- Environmental Factors: Lighting conditions, reflective surfaces, and dust can affect sensor performance.

- Software Development: Custom algorithms may be needed for specific applications.

Future Trends in 3D Vision Systems for Robots

The future of 3D vision systems for robots looks promising with continuous advancements:

- AI Integration: Machine learning improves object recognition and decision-making.

- Miniaturization: Smaller, cheaper sensors will enable wider adoption.

- Cloud Processing: Offloading data processing to the cloud reduces onboard hardware needs.

- Multi-Sensor Fusion: Combining multiple 3D vision technologies for greater robustness.

- Enhanced Real-Time Capabilities: Faster processing enables more responsive and adaptive robots.

How to Choose the Right 3D Vision System for Your Robot

Selecting a suitable 3D vision system depends on several factors:

- Application Requirements: Precision, speed, and environment type.

- Budget Constraints: Balance between cost and performance.

- Integration Complexity: Compatibility with existing robotic hardware and software.

- Environmental Conditions: Indoor vs. outdoor use, lighting, and obstacles.

- Maintenance and Support: Availability of vendor support and ease of calibration.

Conclusion

3D vision systems for robots are reshaping the automation landscape by providing machines with enhanced depth perception and spatial understanding. These technologies empower robots to perform complex, dynamic tasks with higher precision, flexibility, and safety than ever before.

As industries increasingly adopt robotics for efficiency and innovation, understanding and leveraging 3D vision will be crucial for staying competitive. Whether you are developing new robotic solutions or upgrading existing systems, investing in the right 3D vision technology can deliver significant advantages in performance and ROI.

If you want to stay ahead in the robotics revolution, exploring and integrating advanced 3D vision systems is no longer optional — it’s essential.

Discover how uplifting words can shape your mindset in our deep dive into why quotes matter in everyday life.